Why the Right Solar Panel Wiring Tools Matter

Installing solar panels yourself? Having the right solar panel wiring tools makes all the difference between a weekend project and a month-long headache.

This guide is for DIY homeowners, solar installers, and anyone looking to wire solar systems efficiently without breaking the budget. The right tools don’t just speed up your work—they help you avoid costly mistakes and dangerous shortcuts.

We’ll cover the essential hand tools that cut installation time in half, plus specialized testing equipment that catches problems before they become expensive repairs. You’ll also discover organization solutions that keep your workspace clean and your tools within reach when you need them most.

Essential Hand Tools for Faster Solar Installations

Wire Strippers That Cut Installation Time in Half

Quality wire strippers make the difference between a smooth solar panel wiring job and a frustrating afternoon of damaged cables. Professional-grade automatic wire strippers can process multiple wire gauges without manual adjustment, saving precious minutes on every connection. Look for models that handle 10-18 AWG wire sizes, which covers most residential solar applications.

The best solar installation strippers feature precision cutting mechanisms that prevent nicking the conductor underneath. Damaged wire strands create resistance points that can cause hot spots and reduce system efficiency over time. Klein Tools and Ideal Industries manufacture strippers specifically designed for outdoor electrical work, with hardened steel cutting edges that stay sharp through hundreds of strips.

Consider investing in strippers with built-in crimping capabilities. These combo tools eliminate the need to switch between tools constantly, keeping your workflow smooth. Models with comfortable grips and spring-loaded handles reduce hand fatigue during long installation days. Some advanced strippers even include wire gauging slots, allowing you to verify wire size before cutting.

Multi-Purpose Crimping Tools for Professional Connections

Professional solar installations demand reliable connections that withstand decades of weather exposure. A quality crimping tool creates mechanically sound joints that resist corrosion and maintain low resistance over time. MC4 connector crimping tools are essential for solar panel wiring, as these connectors are industry standard for panel interconnections.

Hydraulic crimping tools provide consistent compression force that ensures proper connection every time. Unlike manual crimpers, hydraulic models eliminate guesswork and prevent under-crimped connections that could fail in the field. Panduit and TE Connectivity offer crimpers with interchangeable dies that accommodate different connector types, from MC4s to ring terminals.

Ratcheting crimpers deserve special attention for their ability to prevent incomplete crimps. These tools lock in position until proper compression is achieved, then release automatically. This feature prevents you from accidentally releasing pressure too early, which could result in loose connections. Look for models with color-coded die sets that match standard wire gauge color codes.

For high-volume installations, consider battery-powered crimping tools. These reduce operator fatigue and increase consistency across multiple connections. While the initial investment is higher, the time savings add up quickly on larger projects. DeWalt and Milwaukee manufacture cordless crimpers that work with standard solar industry dies.

Heavy-Duty Cable Cutters for Clean, Efficient Cuts

Clean cable cuts are critical for proper connection integrity in solar panel wiring systems. Ragged or crushed cable ends can prevent proper insertion into connectors and create resistance points. Heavy-duty cable cutters designed for electrical work provide the leverage needed to slice through large gauge DC cables cleanly.

Ratcheting cable cutters multiply your cutting force, making it possible to cut through 4/0 AWG cable with minimal effort. These tools use a progressive cutting action that prevents cable crushing, which can damage conductor strands. The compound leverage system in quality cutters like those from Southwire or Greenlee reduces the hand force required by up to 50%.

For thick grounding cables and main DC runs, hydraulic cable cutters offer the ultimate in cutting power. These tools can slice through cables up to 2 inches in diameter with ease. While they’re a significant investment, they pay for themselves quickly on projects involving heavy gauge wiring. Hydraulic cutters also produce perfectly square cuts that fit properly in large lugs and terminals.

Sharp cutting blades are non-negotiable for professional results. Look for cutters with replaceable or sharpenable blades. Dull blades crush cables instead of cutting them cleanly, potentially damaging expensive conductors. Some manufacturers offer carbide-edged blades that maintain sharpness longer than standard steel, reducing blade replacement frequency.

Battery-powered cable cutters represent the latest evolution in cutting technology. These tools combine the power of hydraulic cutters with the convenience of cordless operation. They’re particularly valuable when working in areas without easy access to power sources or when cutting cables already installed in tight spaces.

Specialized Measurement and Testing Equipment

Digital Multimeters for Quick System Diagnostics

A quality digital multimeter serves as your eyes and ears when working with solar panel wiring systems. These devices measure voltage, current, and resistance with precision that can mean the difference between a successful installation and hours of troubleshooting. Modern solar installations demand multimeters capable of handling DC measurements up to 1000V, as string voltages can reach dangerous levels even in residential systems.

The best multimeters for solar work feature large, backlit displays that remain readable in bright sunlight. Look for models with CAT III 1000V safety ratings and true RMS measurement capabilities. Auto-ranging functions save precious time during diagnostics, while data logging features help track system performance over time. Professional installers often prefer multimeters with built-in temperature sensors, allowing simultaneous monitoring of electrical parameters and ambient conditions that affect panel performance.

When selecting a multimeter, consider models with dedicated solar functions like irradiance measurement or specialized DC current ranges. These features streamline the testing process and reduce the need for multiple instruments on job sites.

MC4 Connector Testers That Prevent Costly Mistakes

MC4 connectors form the backbone of modern solar panel wiring, and their proper installation directly impacts system reliability and safety. Faulty connections create resistance, leading to power losses, heat generation, and potential fire hazards. MC4 connector testers eliminate guesswork by verifying proper crimping force and electrical continuity before energizing the system.

Professional-grade MC4 testers check both mechanical and electrical integrity. They measure crimping force to ensure connections meet manufacturer specifications, preventing loose connections that degrade over time. These tools also perform continuity tests, identifying breaks in conductors or poor crimping that might not be visible during visual inspection.

Advanced models feature go/no-go indicators with LED displays or audible alerts, making testing quick and foolproof. Some units include torque measurement capabilities for connector assembly verification. Investment in quality MC4 testing equipment pays dividends by preventing callbacks and warranty claims related to connection failures.

Wire Gauge Tools for Accurate Cable Selection

Proper wire sizing prevents voltage drop, overheating, and code violations in solar installations. Wire gauge tools take the guesswork out of cable selection by providing quick, accurate measurements of conductor diameter. These tools prove especially valuable when working with unmarked cables or verifying existing installations during system expansions.

Digital calipers offer the highest accuracy for wire gauge measurement, displaying results in both AWG and metric sizes. Many models store multiple measurements and calculate average wire diameter, accounting for manufacturing tolerances. Some advanced units include built-in lookup tables that correlate wire gauge to ampacity ratings based on installation conditions and temperature derating factors.

Mechanical wire gauge plates provide a backup measurement method that doesn’t rely on batteries or electronics. These simple tools feature precision-drilled holes corresponding to standard wire sizes, allowing quick verification of conductor dimensions. Quality plates include both solid and stranded wire measurements, as stranded conductors measure differently than solid wire of equivalent AWG rating.

Voltage Testers for Safe Working Conditions

Safety takes priority in all electrical work, and solar installations present unique challenges due to high DC voltages that persist during daylight hours. Non-contact voltage testers provide the first line of defense against electrical accidents by detecting energized conductors without physical contact. These tools prove invaluable during troubleshooting and maintenance work on active solar systems.

Modern voltage testers designed for solar applications detect both AC and DC voltages across wide ranges. Look for models with adjustable sensitivity settings and visual/audible indicators that remain effective in noisy outdoor environments. CAT IV safety ratings ensure reliable operation around high-voltage solar arrays, while IP65 or higher ratings protect against dust and moisture encountered on rooftops.

Digital voltage testers offer precise readings that help identify specific voltage levels, while simple proximity detectors provide quick go/no-go assessments for safety verification. Many professionals carry both types, using proximity detectors for initial safety checks and digital models for detailed diagnostics. Battery life becomes critical for these safety-critical tools, making models with low-battery indicators and extended runtime essential choices for professional installers.

Advanced Connector and Junction Tools

MC4 Crimping Tools for Weatherproof Connections

Getting solar panel wiring right means starting with bulletproof connections, and MC4 connectors are the gold standard for outdoor solar installations. But here’s the thing – you can’t just twist these connectors together and hope for the best. You need proper MC4 crimping tools to create connections that’ll withstand decades of weather abuse.

A quality MC4 crimping tool does more than just squeeze metal together. It creates a gas-tight seal that prevents corrosion and maintains electrical integrity through temperature swings, moisture, and UV exposure. The difference between a $15 crimper from the hardware store and a professional-grade tool is massive – we’re talking about the difference between callbacks and satisfied customers.

Professional MC4 crimpers feature ratcheting mechanisms that won’t release until the crimp reaches the proper compression. This eliminates guesswork and ensures consistent results across your entire installation. Look for tools with interchangeable dies that accommodate different wire gauges, typically ranging from 10 AWG to 14 AWG for most residential installations.

The best MC4 crimpers also include built-in wire strippers calibrated specifically for solar applications. This saves time and reduces the chance of nicking conductors during preparation. Some models even feature integrated retention mechanisms that hold the connector in place while you position the wire – a small detail that makes a huge difference when you’re working on a roof in windy conditions.

Heat Guns for Professional Heat Shrink Applications

Every solar installation involves dozens of connections that need weatherproofing, and heat shrink tubing is your best friend for protecting splice points and conductor terminations. But not all heat guns are created equal, and using the wrong tool can literally melt your project.

Variable temperature control is non-negotiable for professional solar work. Different heat shrink materials activate at different temperatures – typically between 200°F and 300°F for standard applications. A quality heat gun lets you dial in the exact temperature needed without overshooting and damaging nearby components.

Digital display models take the guesswork out of temperature management. You can set precise temperatures and monitor them throughout the application process. This consistency is crucial when you’re working with expensive solar panel wiring that can’t be easily replaced if damaged.

Cordless heat guns have revolutionized rooftop installations. No more dragging extension cords across shingles or dealing with limited reach. Modern battery-powered units deliver enough heat for professional applications while giving you the mobility to work efficiently across large arrays.

Connector Assembly Tools That Reduce Labor Hours

Time is money in solar installations, and specialized connector assembly tools can cut your labor hours significantly while improving connection reliability. These tools go beyond basic crimping to streamline the entire connection process.

Multi-function connector tools combine several operations into one smooth workflow. Strip, crimp, and assemble MC4 connectors without switching between multiple tools. Some models even include torque specifications built into the handle, ensuring proper tightness without over-stressing plastic housings.

Spring-loaded connector holders are simple but brilliant time-savers. They secure connectors during assembly, leaving both hands free for wire positioning and crimping. This seemingly minor convenience adds up to hours saved on large installations.

Automatic wire strippers calibrated for solar applications remove exactly the right amount of insulation every time. No measuring, no second-guessing – just consistent results that speed up your workflow while reducing waste and rework.

| Tool Type | Time Savings | Key Benefit |

|---|---|---|

| Multi-function crimper | 30-40% | Eliminates tool switching |

| Spring-loaded holder | 15-20% | Hands-free positioning |

| Auto wire stripper | 25-30% | Consistent strip lengths |

Investing in quality connector assembly tools pays for itself quickly through reduced labor costs and improved installation quality. Your crews work faster, make fewer mistakes, and create more reliable connections that protect your reputation and warranty obligations.

Safety Equipment That Protects Your Investment

Insulated Tool Sets for Electrical Protection

Working with solar panel wiring demands tools that keep you safe from electrical hazards while maintaining efficiency. Insulated hand tools form the backbone of safe electrical work, featuring protective coatings rated for 1000V AC or 1500V DC. These tools prevent accidental contact with live wires during installation and maintenance tasks.

Quality insulated tools include screwdrivers, pliers, wire strippers, and socket sets with bright orange or red handles that clearly identify them as safety equipment. The insulation must meet IEC 60900 standards, which means each tool undergoes rigorous testing to ensure the protective coating won’t crack or wear under normal use.

Professional-grade insulated tool sets typically cost 30-50% more than standard tools, but this investment prevents costly accidents and project delays. Many electricians report that switching to insulated tools actually improved their work speed because they worry less about accidental contact with energized components.

Arc Flash Detection Equipment for Risk Prevention

Arc flash incidents during solar installations can cause severe injuries and equipment damage. Modern arc flash detection devices monitor electrical systems continuously, alerting workers to dangerous conditions before they escalate into full arc events.

Personal arc flash monitors clip onto clothing and sound alarms when they detect the light signature of an developing arc flash. These devices give workers precious seconds to move away from danger zones. Fixed arc flash detectors install permanently in electrical panels and can automatically trip circuit breakers when dangerous arcs develop.

Arc flash detection technology has advanced significantly, with newer models offering:

- Response times under 2 milliseconds

- Integration with existing safety systems

- Wireless communication capabilities

- Battery life exceeding 40 hours

The cost of arc flash detection equipment ranges from $200 for personal monitors to $2,000 for panel-mounted systems, but the protection they provide makes them essential for any serious solar installation operation.

Personal Protective Gear That Meets Industry Standards

Solar installation work requires specific PPE that addresses both electrical and physical hazards. Arc-rated clothing protects against flash incidents, while properly rated hard hats shield workers from falling objects and electrical contact.

Safety glasses with side shields prevent debris and UV exposure, while leather gloves rated for electrical work protect hands during wiring tasks. Class 0 or Class 00 electrical gloves provide additional protection when working near energized equipment.

Fall protection harnesses become critical when installing rooftop systems. Full-body harnesses with shock-absorbing lanyards reduce impact forces if falls occur. Many installers prefer harnesses with tool loops and D-rings positioned for easy access while maintaining three points of contact on ladders or scaffolding.

Grounding Equipment for System Safety

Proper grounding protects both equipment and personnel from electrical faults and lightning strikes. Temporary grounding sets allow safe work on de-energized systems by creating a path for fault currents that would otherwise energize equipment unexpectedly.

Equipment grounding includes copper grounding conductors, grounding electrode conductors, and bonding jumpers that connect all metal components to earth ground. Grounding clamps and lugs must resist corrosion in outdoor environments while maintaining low-resistance connections over decades of service.

Ground fault detection equipment monitors system grounding continuously, alerting operators when ground faults develop that could compromise safety or system performance. These devices help identify problems before they cause equipment damage or create shock hazards for maintenance personnel.

Proper grounding installation requires torque wrenches to achieve specified connection tightness and multimeters capable of measuring low-resistance values accurately. Investment in quality grounding equipment and installation tools prevents costly callbacks and safety incidents throughout the system’s 25-year lifespan.

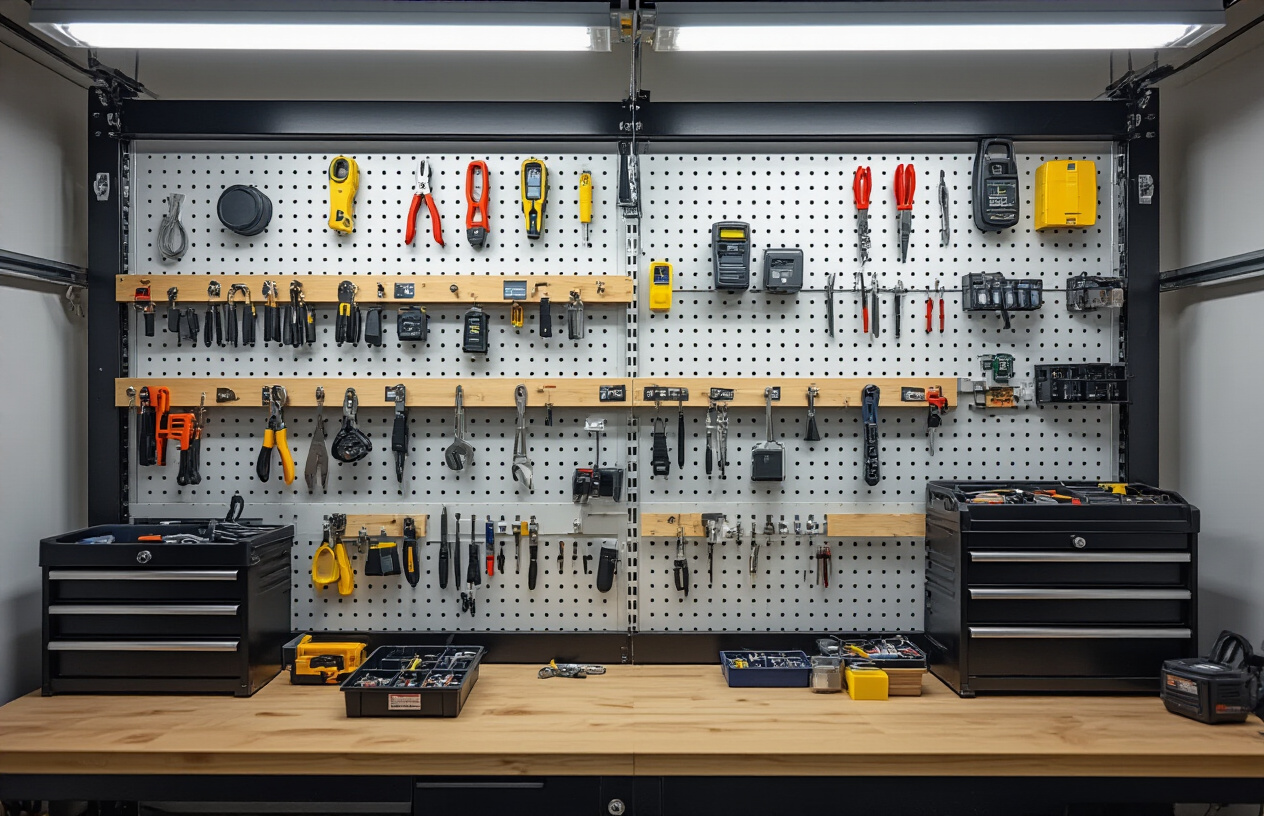

Time-Saving Organization and Storage Solutions

Tool Bags Designed for Solar Technicians

Professional solar installers know that having the right bag can make or break an installation day. The Klein Tools 5141 Electrician’s Tool Bag stands out as a top choice for solar panel wiring work. With its 14 interior and exterior pockets, technicians can organize everything from wire strippers to MC4 connectors without the frustrating search-and-grab that slows down progress.

The Veto Pro Pac Tech series takes organization to another level. These bags feature tool boards that keep hand tools visible and accessible, while the bottom compartment handles bulky items like multimeters and voltage testers. The closed-top design protects sensitive equipment from dust and debris common on solar installation sites.

For rooftop work, weight distribution matters as much as storage capacity. The Husky 18-inch tool bag offers a reinforced bottom and balanced design that won’t throw you off balance when climbing ladders. Its weather-resistant exterior protects tools from moisture during those unpredictable weather changes that can happen mid-installation.

Electrician-specific features make certain bags particularly valuable for solar work. Look for bags with dedicated spots for wire nuts, a tape measure holder, and knife clips. The Custom Leathercraft 1539 includes all these features plus a removable parts tray that’s perfect for sorting different gauge wires during complex solar panel wiring projects.

Parts Organizers That Eliminate Search Time

Nothing kills momentum like digging through loose parts bins looking for the right connector. Parts organizers designed for electrical work transform chaotic collections into systematic storage that speeds up every installation phase.

The Akro-Mils 10124 parts organizer cabinet features 24 drawers with clear fronts, making it easy to spot MC4 connectors, fuses, and junction box hardware at a glance. Each drawer holds enough components for multiple installations, and the stackable design means you can expand storage as your inventory grows.

Portable organizers work better for smaller crews or residential installations. The CRAFTSMAN Versastack system connects multiple organizers while keeping individual boxes lightweight enough for one person to carry. The clear lids let you see contents without opening every box, and the customizable dividers adapt to different component sizes.

Small parts like screws, bolts, and wire nuts disappear easily on job sites. The Craftsman 20-compartment organizer addresses this with secure latching and individual compartments sized for electrical hardware. Each section closes independently, so opening one compartment won’t spill the contents of another.

For crews handling multiple projects simultaneously, color-coded organizers prevent mix-ups between job sites. Assign each project a different color organizer, and crew members can grab the right parts for their specific installation without confusion or delays.

Mobile Tool Carts for Large Installation Sites

Large commercial solar installations require tool mobility that standard bags can’t provide. Rolling tool carts bring the workshop to wherever work happens, eliminating multiple trips back to the truck for different tools and parts.

The Keter Masterloader cart combines storage capacity with job site durability. Its 22-gallon storage bin holds bulk items like conduit and cable runs, while the upper toolbox organizes precision instruments and smaller tools. All-terrain wheels handle rough surfaces common around construction sites and solar farms.

Multi-drawer carts work well for teams with specialized roles. The Craftsman 3-drawer cart lets you dedicate one drawer to measurement tools, another to cutting and stripping equipment, and the third to connection hardware. The top surface provides a clean work area for preparing connections or reviewing installation drawings.

Power tool storage becomes critical on sites where cordless tools handle most of the work. The DeWalt ToughSystem cart includes dedicated spots for drill batteries and chargers, keeping power tools ready when you need them. The modular design lets you stack additional storage boxes as project requirements change.

Weather protection matters for sensitive equipment like digital multimeters and thermal cameras. Look for carts with weatherproof compartments or add-on covers that shield expensive instruments from rain and direct sunlight while keeping them easily accessible throughout the workday.

Solar installations don’t have to drain your wallet or eat up your entire weekend. With the right tools in your toolkit, you can cut installation time in half while avoiding costly mistakes that come back to haunt you later. From basic hand tools that speed up panel mounting to specialized testing equipment that catches problems before they become expensive headaches, investing in quality solar wiring tools pays for itself quickly.

The smart move is starting with essential safety gear and reliable measurement tools, then building your collection as you take on more projects. Your future self will thank you when you’re finishing installations faster, working more safely, and having everything organized right where you need it. Stop wrestling with subpar tools and start making solar installations work for you instead of against you.

Frequently Asked Questions (FAQs)

1. Can investing in quality tools really save money on solar installations?

Yes, investing in quality tools reduces installation time, minimizes mistakes, and helps avoid costly repairs or replacements. Over time, reliable tools pay for themselves by increasing efficiency and ensuring long-term system reliability.

2. What are the most essential tools for solar panel wiring?

The most essential tools include wire strippers, multi-purpose crimping tools, heavy-duty cable cutters, digital multimeters, MC4 connector crimpers, and voltage testers. Each tool plays a critical role in ensuring safe, efficient, and reliable solar panel installations.

3. Why is it important to use specialized tools instead of basic household tools for solar wiring?

Specialized solar wiring tools are designed for specific tasks and wire sizes, which helps prevent damage to cables, ensures secure connections, and improves overall safety. Using the wrong tool can lead to poor performance, increased safety risks, and potential system failures.

4. How can I ensure my solar panel wiring is safe and up to code?

Always use tools that meet industry safety standards, such as IEC 60900 for insulation. Follow manufacturer guidelines, double-check all connections with appropriate testing equipment, and consult local electrical codes. When in doubt, consider hiring a licensed professional.

5. What’s the benefit of using organization solutions like tool bags and parts organizers?

Tool bags and parts organizers help keep your equipment accessible, protected, and well-sorted. This organization saves time during installation, reduces the likelihood of losing critical components, and helps maintain a safer, cleaner workspace.

Disclaimer:

The information provided in this blog is for general educational and informational purposes only. While every effort has been made to ensure accuracy, solar panel installation and electrical work involve inherent risks. Always follow local codes, manufacturer guidelines, and safety regulations. If you are not a licensed professional, consult with or hire a qualified electrician or solar installer before attempting any electrical or solar system work. The author and publisher are not responsible for any damages, injuries, or losses resulting from the use or misuse of the information contained herein. Use all tools and equipment according to manufacturer instructions and prioritize safety at all times.

If you liked this post Visit Other Posts Click Here.